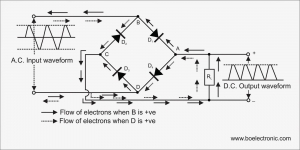

Working principle of Bridge Rectifier

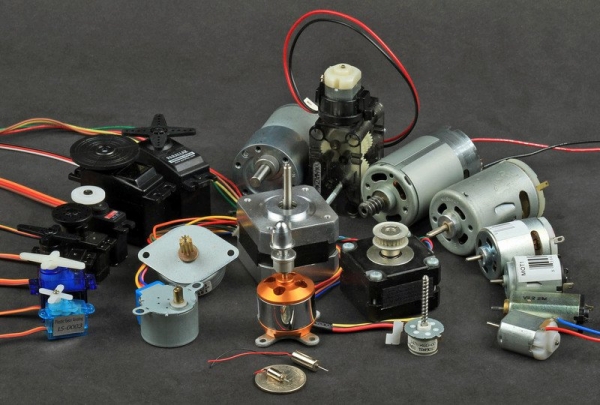

MOTOR

A motor is an extended version of a transformer. Here we can introduce the analogy between a transformer and a motor that is a motor is like a transformer with a moving secondary. The primary that is not moving is called stator and the secondary that is moving is called rotor. The type of motor that is used worldwide with a greater percentage is the three phase induction motor.

The principle is somewhat like a transformer. If we place three coil at 120 degree physical alignment and also apply three phase ac supply which is also with 120 degree electrical phase relation, then the resultant flux, that is created from the vectorial space summation of the three phase fluxes, will rotate at the frequency of the supply voltage. Here the magnitude of the flux is same throughout the rotation. Now this revolving flux will cut the rotor and there will be an induced voltage across the rotor as well. As the rotor is short circuited there will be a flow of current through the short circuited loop. This current will create a flux which will interact with the revolving flux. There will be a force exerted upon this flux from the rotor. The current in the rotor will flow in such a direction so that it can decrease the rate of change of flux from which it is created. As a result the rotor will try to revolve in the direction of the revolving flux to reduce the rate of change of flux cut. When the rotor revolves then the relative velocity with the stator decrease and the rotor will rotate with a slip so that it can provide the necessary torque of the load.

THREE-PHASE AC INDUCTION MOTORS

Where a polyphase electrical supply is available, the three-phase (or polyphase) AC induction motor is commonly used, especially for higher-powered motors. The phase differences between the three phases of the polyphase electrical supply create a rotating electromagnetic field in the motor.

Through electromagnetic induction, the time changing and reversing (alternating in direction polyphase currents) rotating magnetic field induces a time changing and reversing (alternating in direction)current in the conductors in the rotor; this sets up a time changing and counterbalancing moving electromagnetic field that causes the rotor to turn in the direction the field is rotating. The rotor always moves (rotates) slightly behind the phase peak of the primary magnetic field of the stator and is thus always moving slower than the rotating magnetic field produced by the polyphase electrical supply.

Induction motors are the workhorses of industry and motors up to about 500 kW (670 horsepower) in output are produced in highly standardized frame sizes, making them nearly completely interchangeable between manufacturers. Very large induction motors are capable of tens of thousands of kW in output, for pipeline compressors, wind-tunnel drives and overland conveyor systems.

There are two types of rotors used in induction motors: squirrel cage rotors and wound rotors.

SQUIRREL-CAGE ROTOR

Most common AC motors use the squirrel cage rotor, which will be found in virtually all domestic and light industrial alternating current motors. The squirrel cage takes its name from its shape - a ring at either end of the rotor, with bars connecting the rings running the length of the rotor. It is typically cast aluminum or copper poured between the iron laminates of the rotor, and usually only the end rings will be visible.

WOUND ROTOR

An alternate design, called the wound rotor, is used when variable speed is required. In this case, the rotor has the same number of poles as the stator and the windings are made of wire, connected to slip rings on the shaft. Carbon brushes connect the slip rings to an external controller such as a variable resistor that allows changing the motor's slip rate.

THREE-PHASE AC SYNCHRONOUS MOTORS

If connections to the rotor coils of a three-phase motor are taken out on slip-rings and fed a separate field current to create a continuous magnetic field (or if the rotor consists of a permanent magnet), the result is called a synchronous motor because the rotor will rotate synchronously with the rotating magnetic field produced by the polyphase electrical supply. The synchronous motor can also be used as an AC generator or alternator.

One use for this type of motor is its use in a power factor correction scheme. They are referred to as synchronous condensers. This exploits a feature of the machine where it consumes power at a leading power factor when its rotor is over excited. It thus appears to the supply to be a capacitor, and could thus be used to correct the lagging power factor that is usually presented to the electric supply by inductive loads. The excitation is adjusted until a near unity power factor is obtained (often automatically). Machines used for this purpose are easily identified as they have no shaft extensions. Synchronous motors are valued in any case because their power factor is much better than that of induction motors, making them preferred for very high power applications.

TWO-PHASE AC SERVO MOTORS

A typical two-phase AC servo motor has a squirrel-cage rotor and a field consisting of two windings: a constant-voltage (AC) main winding and a control-voltage (AC) winding in quadrature with the main winding as to produce a rotating magnetic field. The electrical resistance of the rotor is made high intentionally so that the speed-torque curve is fairly linear. Two-phase servo motors are inherently high-speed, low-torque devices, heavily geared down to drive the load.

SINGLE-PHASE AC INDUCTION MOTORS

Three-phase motors inherently produce a rotating magnetic field. However, when only single-phase power is available, the rotating magnetic field must be produced using other means. Several methods are commonly use. A common single-phase motor is the shaded-pole motor, which is used in devices requiring low starting torque, such as electric fans or other small household appliances. In this motor, small single-turn copper "shading coils" create the moving magnetic field. Another common single-phase AC motor is the split-phase induction motor, commonly used in major appliances such as washing machines and clothes dryers. Compared to the shaded pole motor, these motors can generally provide much greater starting torque by using a special startup winding in conjunction with a centrifugal switch. Another variation is the permanent-split capacitor (PSC) motor (also known as a capacitor start and run motor). This motor operates similarly to the capacitor-start motor described above, but there is no centrifugal starting switch, and the start windings (second windings) are permanently connected to the power source (through a capacitor), along with the run windings. PSC motors are frequently used in air handlers, blowers, and fans (including ceiling fans) and other cases where a variable speed is desired.

REPULSION MOTOR

Repulsion motors are wound-rotor single-phase AC motors that are similar to universal motors. In a repulsion motor, the armature brushes are shorted together rather than connected in series with the field.

SINGLE-PHASE AC SYNCHRONOUS MOTORS

Small single-phase AC motors can also be designed with magnetized rotors (or several variations on that idea). The rotors in these motors do not require any induced current so they do not slip backward against the mains frequency. Instead, they rotate synchronously with the mains frequency. Because of their highly accurate speed, such motors are usually used to power mechanical clocks, audio turntables, and tape drives; formerly they were also much used in accurate timing instruments such as strip-chart recorders or telescope drive mechanisms. The shaded-pole synchronous motor is one version.

BRUSHED DC ELECTRIC MOTOR

A brushed DC motor is an internally commutated electric motor designed to be run from a DC power source.

RELUCTANCE MOTOR

A reluctance motor is a type of synchronous electric motor which induces non-permanent magnetic poles on the ferromagnetic rotor. Torque is generated through the phenomenon of magnetic reluctance. A reluctance motor, in its various incarnations, may be known as a:

• Synchronous reluctance motor

• Variable reluctance motor

• Switched reluctance motor (SRM)

• Variable reluctance stepping motor SRM's are used in some washing machine designs. SRM's are commonly used in the control rod drive mechanisms of nuclear reactors.

UNIPOLAR MOTOR

A unipolar motor is a type of small DC electric motor commonly found in small, portable cassette players. Its name is derived from its construction, which employs a magnetic strip wrapped around the inner wall of the housing such that one of its poles faces the inside, while the other faces outward.

LINEAR MOTOR

A linear motor or linear induction motor is essentially a multi-phase alternating current electric motor that has had its stator "unrolled" so that instead of producing a torque it produces a linear force along its length. When a linear motor is used to accelerate beams of ions or subatomic particles, it is called a particle accelerator. The design is usually rather different as the particles move close to the speed of light and are generally electrically charged.

BRUSHLESS DC ELECTRIC MOTOR

A brushless DC motor (BLDC) is a synchronous electric motor which is powered by direct-current electricity (DC) and which has an electronically controlled commutation system, instead of a mechanical commutation system based on brushes. In such motors, current and torque, voltage and rpm are linearly related. BLDC motors can potentially be deployed in any area currently fulfilled by brushed DC motors. Cost and control complexity prevents BLDC motors from replacing brushed motors in most common areas of use. Nevertheless, BLDC motors have come to dominate many applications: Consumer devices such as computer hard drives, CD/DVD players, and PC cooling fans use BLDC motors almost exclusively. Low speed, low power brushless DC motors are used in direct drive turntables. High power BLDC motors are found in electric vehicles and some industrial machinery. These motors are essentially AC synchronous motors with permanent magnet rotors.

STEPPER MOTOR

A stepper motor (or step motor) is a brushless, synchronous electric motor that can divide a full rotation into a large number of steps. Computer-controlled stepper motors are one of the most versatile forms of positioning systems. They are typically digitally controlled as part of an open loop system, and are simpler and more rugged than closed loop servo systems.

Industrial applications are in high speed pick and place equipment and multi-axis machine CNC machines often directly driving lead screws or ball screws. In the field of lasers and optics they are frequently used in precision positioning equipment such as linear actuators, linear stages, rotation stages, goniometers, and mirror mounts. Other uses are in packaging machinery, and positioning of valve pilot stages for fluid control systems.

Commercially, stepper motors are used in floppy disk drives, flatbed scanners, computer printers, plotters and many more devices.

Related Post